Solutions for Sourcing the Most Efficient Breadcrumbing Machines Worldwide

Table of Contents

- The Evolution of Breadcrumbing Machines: From Traditional to High-Tech Solutions

- Exploring the Global Market: Top Manufacturers of Breadcrumbing Machines in 2023

- Quality Upgrades in Chinese Manufacturing: How They Meet Global Standards

- Efficiency Metrics: Comparing Output Rates of Leading Breadcrumbing Machines

- Sustainability in Production: Eco-Friendly Innovations in Breadcrumbing Technology

- Future Trends: Automation and AI in the Development of Breadcrumbing Machines

- Enhancing Efficiency: The Impact of Commercial Japanese-style Karaage Chicken Battering Machines on Poultry Processing Productivity

- FAQS

- Related Posts

You know, in the fast-changing world of food processing, having efficient machinery is more important than ever—especially when it comes to specialized equipment like the Breadcrumbing Machine. I read somewhere that, according to Grand View Research, the global market for food machinery is expected to hit around $28.6 billion by 2025. That’s mainly because people are now craving more processed foods, plus there’s a constant push for better, more innovative machine designs.

As a major player in this field, Shandong Kexinde Machinery Technology Co., Ltd. really focuses on creating cutting-edge solutions that cater to different industries—whether it’s food and beverages, healthcare products, or pharmaceuticals. With our expertise in designing and building advanced Breadcrumbing Machines, we’re all set to meet the rising demand for both efficiency and top-notch quality in food processing worldwide.

The Evolution of Breadcrumbing Machines: From Traditional to High-Tech Solutions

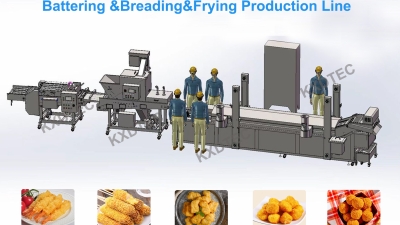

Over the years, the way breadcrumbing machines have evolved has totally transformed the food processing world. Gone are the days of manual work and simple machines, which often meant uneven quality and slow production. Now, thanks to tech breakthroughs, we’ve got machines that not only make the process smoother but also improve accuracy and can handle bigger production runs. Today’s equipment can whip up breadcrumbs in all sorts of sizes, textures, and flavors, really meeting the wide range of needs in the food industry.

Take Shandong Kexinde Machinery Technology Co., Ltd., for example. We’re right there on the cutting edge, designing top-of-the-line breadcrumbing machines specifically for food and beverage manufacturers. We’re all about innovation — our machines are packed with the latest features to boost efficiency without sacrificing quality. Plus, with automation and user-friendly controls, we make it easier for food producers to keep up with ever-growing consumer demands and set new standards in the industry.

Solutions for Sourcing the Most Efficient Breadcrumbing Machines Worldwide

| Machine Type | Automation Level | Production Capacity (kg/h) | Energy Efficiency (%) | Price Range ($) |

|---|---|---|---|---|

| Traditional Breadcrumbing Machine | Low | 200 | 60 | 2,000 - 5,000 |

| Semi-Automatic Breadcrumbing Machine | Medium | 500 | 75 | 5,000 - 10,000 |

| Fully Automatic High-Tech Machine | High | 1,000 | 90 | 10,000 - 25,000 |

| Compact Breadcrumbing Machine | Medium | 300 | 65 | 3,000 - 7,000 |

Exploring the Global Market: Top Manufacturers of Breadcrumbing Machines in 2023

You know, the global market for breadcrumbing machines is really set to grow a lot in 2023. It's mainly because more and more industries, like food processing and hospitality, are showing a big interest in these machines. Some recent reports even suggest that by the end of the year, this market could be worth around $1.5 billion. That's pretty impressive, especially considering it’s been growing at about 5.2% annually since 2020. A lot of this upward push comes from new tech and automation improvements, which means manufacturers can make high-quality breadcrumbs faster and more efficiently than ever.

Big players like Coperion and SMS Group are really stepping up their game, adopting all sorts of innovative solutions just to stay ahead. They're working with smart tech—think IoT-enabled machinery—that lets them monitor and optimize production in real-time. Plus, sustainability is no longer just a buzzword; it’s a real priority now. Many companies are investing in energy-saving machines, and reports show that about 60% of them are designing equipment with eco-friendliness in mind to cut down their carbon footprint. As this market keeps evolving, these key companies are leading the way in quality and efficiency, shaping what’s next for breadcrumb production.

Quality Upgrades in Chinese Manufacturing: How They Meet Global Standards

The world of breadcrumbing machine manufacturing has really changed a lot these days, especially in China. They’ve been stepping up their game in quality, actually often surpassing some of the global standards out there. Thanks to increased investment in new tech and skilled workers, Chinese manufacturers are now able to produce machines that are super efficient and meet the demands of the international market. This isn’t just about better performance; these machines are built to last and be reliable, which makes them a pretty attractive option for businesses around the world.

When you’re searching for breadcrumbing machines, it’s a smart move to look for manufacturers that have solid international certifications like ISO or CE. Those marks tell you the machines have been thoroughly tested for performance, safety, and environmental impact — and that can save you a headache (and money) down the road with fewer maintenance issues.

Oh, and don’t forget to ask vendors if they offer customization. Having machinery that’s tailored to your specific needs — like your production volume, the materials you work with, or special features — can make a huge difference in how efficiently your operation runs. Just make sure you talk through your requirements with potential suppliers so the machines integrate smoothly into your process.

Keep these things in mind, and you’ll be better equipped to pick a breadcrumbing machine that fits your production goals and keeps everything running smoothly.

Efficiency Metrics: Comparing Output Rates of Leading Breadcrumbing Machines

You know, in the fast-changing world of food production, how well breadcrumbing machines perform can really make a difference in how much gets done every day. Recent numbers show that U.S. agricultural productivity has nearly tripled since 1948—it’s been growing at about 1.46% a year up until 2021. This kind of progress just goes to show how important it is to keep an eye on the output of those top breadcrumbing machines because they can really help improve the overall flow of production lines.

If you're trying to compare different breadcrumbing machines, there are a few key things to look at: how often the machines are used, how much downtime they have, the quality of the output, how often they need maintenance, and how much energy they use. Keeping track of these things regularly can really give a boost to efficiency. For instance, setting up preventive and predictive maintenance can help avoid those unexpected breakdowns that end up costing a lot of time and money—something pretty common in many manufacturing plants.

A few tips for making these machines more efficient? First off, schedule regular maintenance to prevent them from breaking down. Also, investing in tech that provides real-time performance data can be a game-changer. Plus, understanding how different models use energy can help figure out which one is the best fit for your specific needs. If you focus on these strategies, you’re basically giving your operation the best shot at being as productive as possible.

Sustainability in Production: Eco-Friendly Innovations in Breadcrumbing Technology

Lately, it feels like the breadcrumbing industry is really starting to shift towards being more eco-friendly. More and more manufacturers are jumping on the sustainability bandwagon, adopting greener practices in how they make their machines. I came across a 2022 report from Global Market Insights, and it said that the demand for sustainable food processing tech is expected to grow by over 10% each year. That pretty much shows how both consumers and businesses are becoming way more aware of the environmental impact. Because of this, companies that make breadcrumbing machines are stepping up their game—focusing on cutting down energy use and cutting back on waste during production.

Future Trends: Automation and AI in the Development of Breadcrumbing Machines

Lately, the way breadcrumbing machines are evolving has really picked up, thanks to all the progress in automation and AI. It’s pretty exciting because these advancements don’t just speed things up—they also make the production more precise and consistent. When manufacturers start using smarter tech, we’re looking at machines that can run on their own and even tweak their own settings based on live data. That means less waste and more output without breaking a sweat.

Here’s a little tip: if you want to stay ahead of the game in this super competitive market, it’s a good idea to invest in training your team. Getting everyone comfortable with these high-tech machines and understanding AI can really pay off — it empowers operators to make smarter decisions that keep the production process running smoothly.

And then there’s AI-powered predictive maintenance, which is changing the way companies handle machine upkeep. With sensors and machine learning in the mix, businesses can actually spot potential issues before they happen. That way, they cut down on unexpected downtimes and save a bunch on repairs. It’s all about being proactive, making operations much smoother, and boosting overall productivity.

A quick tip for companies: try to set up solid data analysis tools that keep track of how your machines are performing. The insights you get from this stuff can really help you fine-tune your processes and catch areas that could use a little improvement, all in real time.

Enhancing Efficiency: The Impact of Commercial Japanese-style Karaage Chicken Battering Machines on Poultry Processing Productivity

In the fast-paced world of poultry processing, efficiency is paramount, and the introduction of commercial Japanese-style Karaage chicken battering machines is reshaping industry standards. These advanced machines are specifically designed to cater to various battering, coating, and dusting requirements, significantly enhancing productivity on the production line. According to industry reports, automating the coating process can increase production rates by up to 50%, while also ensuring a consistent and high-quality finish that manual methods struggle to replicate.

Equipped with adjustable speed settings and various models tailored to meet specific production needs, these machines allow processors to optimize their operations. The incorporation of conveyor belts facilitates smooth transitions between different stages of production, reducing bottlenecks typically caused by manual handling. Data from recent surveys indicate that companies utilizing automated battering machines have reported a notable decrease in labor costs, with a potential reduction of 20-30% in workforce requirements for coating processes alone.

Moreover, the utilization of these innovative machines not only streamlines operations but also improves food safety and hygiene standards. Automated systems minimize direct handling of raw products, which lowers the risk of contamination, a critical factor in maintaining compliance with increasingly stringent industry regulations. Thus, the impact of commercial Japanese-style Karaage chicken battering machines extends beyond productivity, fostering a safer and more efficient processing environment.

FAQS

: The breadcrumbing machine market is projected to reach a valuation of approximately $1.5 billion by the end of 2023.

The market is showcasing a CAGR of around 5.2% from 2020 to 2023.

Leading manufacturers in the sector include Coperion and SMS Group.

Manufacturers are implementing smart technologies, such as IoT-enabled machinery, for real-time monitoring and improved production processes.

Nearly 60% of manufacturers are prioritizing sustainability in equipment design to reduce their carbon footprint.

Increasing consumer and business awareness regarding environmental impact is driving the demand for sustainable food processing technologies, projected to grow by over 10% annually.

Machines utilizing advanced engineering and design can reduce energy usage by up to 30%.

Innovations such as energy-efficient motors, low-impact materials, biodegradable lubricants, and recyclable components are becoming more mainstream.

These innovations enhance operational efficiency and appeal to environmentally conscious consumers, driving a favorable market response.

Related Posts

-

Innovative Solutions for Best Banana Plantain Chips Production Line Overcoming Common Industry Challenges

-

Leading the Way in Export Strength: The Best Chicken Basket Washing Machine from China

-

Common Challenges Faced with the Best Industrial Tray Washing Machines

-

Upgrade Your Frying Experience with China Made Best Stainless Steel French Fries Frying Machines

-

15 Best Practices for Maximizing Your Tempura Nugget Line Efficiency

-

Navigating Industry Standards and Challenges for the Best Automatic Breading Machine