Revolutionizing Snack Production: 5 Innovative Examples of Automatic Snacks Frying Machines Transforming the Industry

Table of Contents

- Emerging Trends in Automatic Snacks Frying Technology

- Key Features of Innovative Snack Frying Machines

- Case Study: Success Stories from Leading Snack Manufacturers

- Energy Efficiency: How Automation Saves Costs in Snack Production

- The Future of Snack Production: Smart Machines and AI Integration

- Maximizing Efficiency and Quality in Food Production: Insights from Recent Industry Reports on Commercial Frying Equipment

- FAQS

- Conclusion

- Related Posts

In today's fast-moving world, everyone seems to be after snacks that are both quick and tasty, which is really pushing the food industry to get more innovative and adapt fast. One of the biggest game-changers has gotta be the Automatic Snacks Frying Machine — it's totally changed the way snacks are made. Companies like Shandong Kexinde Machinery Technology Co., Ltd. are leading the charge here, focusing on designing, building, and selling some seriously advanced food equipment. These automatic fryers don’t just speed things up—they also make sure every snack comes out tasting great and consistent every time. In this blog, I want to share five cool examples of how these machines are shaking up snack production, showing just how much tech is helping meet what consumers want and making things run smoother. Come along as we explore this exciting shift happening in snack manufacturing — it’s pretty fascinating stuff!

Emerging Trends in Automatic Snacks Frying Technology

As the snack food industry keeps growing and changing, automatic snack frying tech is really making big leaps forward. It’s not just about cranking out snacks faster; the quality of what you get out is improving too. We’re seeing a real shift towards machines that are more energy-efficient—saving money on energy bills while also being kinder to the environment. Plus, with fancy sensors and AI now in the mix, these machines can monitor things in real time, making sure every batch is fried perfectly. No overcooking, which means better flavor and texture every time.

If you’re thinking about upgrading your frying setup, here’s a tip: look for machines that are modular. Having a flexible design makes maintenance a lot easier, and it’s simpler to upgrade parts as new tech comes along. It’s also smart to get equipment with advanced monitors to keep an eye on oil quality and temperature. This really helps produce snacks that are healthier and keep their nutritional punch.

And don’t forget about customization — choosing a machine that can adjust frying profiles is a game changer. Different snacks need different frying conditions, and a versatile machine can handle all that without sacrificing quality. Using these kinds of features not only makes your process more efficient but also keeps your business ahead of the game in the fast-evolving snack world.

Key Features of Innovative Snack Frying Machines

These days, the snack industry’s really changing thanks to the latest frying machines. They're not just faster—they actually help make the snacks better quality-wise. A lot of these new machines come with cool features that make the frying process smoother and ensure every batch tastes great and stays consistent. For example, many have super accurate temperature controls that keep things just right—no more undercooked or burnt snacks. That kind of precision is a game-changer for getting that perfect crunch and flavor, especially as people's tastes keep evolving.

These days, the snack industry’s really changing thanks to the latest frying machines. They're not just faster—they actually help make the snacks better quality-wise. A lot of these new machines come with cool features that make the frying process smoother and ensure every batch tastes great and stays consistent. For example, many have super accurate temperature controls that keep things just right—no more undercooked or burnt snacks. That kind of precision is a game-changer for getting that perfect crunch and flavor, especially as people's tastes keep evolving.

Another neat thing is the automated oil filtering. It keeps the oil cleaner during frying, which means the snacks are safer and tastier. Plus, filtering out impurities all the time helps the oil last longer, so you're not wasting as much and can keep things healthier—you know, fresher snacks for everyone. Some machines even come with smart tech that lets you monitor and tweak things on your phone or tablet in real-time. It’s pretty slick because it makes managing quality way easier. Overall, these tech upgrades really show how much automation and innovation are pushing snack-making forward these days.

Case Study: Success Stories from Leading Snack Manufacturers

So, if you’re into the snack world, you'll probably notice that automation has really been shaking things up. It’s not just about making things faster; it’s also about keeping that consistent quality we all crave. I recently came across a market report that says the global market for automatic snack frying machines is expected to grow at around 5.8% annually from 2023 to 2028. Pretty impressive, right? The main driver behind this? The huge rise in demand for processed, ready-to-eat snacks — people love convenience these days. Companies are jumping on board, adopting cutting-edge frying tech that doesn't just boost efficiency but also helps keep the snack quality top-notch. It’s giving them a real leg up in a pretty crowded market.

One standout player in this scene is Shandong Kexinde Machinery Technology Co., Ltd. — they’re known for their high-tech food machinery solutions. What’s cool about them? They’re blending sophisticated control systems with energy-efficient designs. This means they’re not just pumping out more snacks to meet demand, but they’re also focusing on sustainability. Some case studies even show that their automatic frying machines can cut down cooking times by up to 30%, and oil use by about 20%. That’s a big deal when it comes to saving costs and improving margins. Companies using this kind of technology are truly setting new standards for quality and efficiency, which is really transforming the snack food game overall.

Energy Efficiency: How Automation Saves Costs in Snack Production

You know, in the snack production world, things are always changing, and one big shift we've seen is focus on energy efficiency — especially through automation. Adding high-tech automatic frying machines has really made a difference. Not only can manufacturers cut down on energy use, but they also keep chill with top-notch quality. These smart machines give you precise control over the process, so the frying is just right — which means better snacks and less waste falling through the cracks.

But it doesn’t stop there. Automation really steps up water management too. The modern washing systems make sanitation a breeze, allowing companies to move quickly from batch to batch. That’s a win for saving labor costs and keeping everything cleaner and safer overall. Plus, companies like Shandong Kexinde Machinery Technology Co., Ltd. are constantly pushing out new and better machinery, so the chances to save energy and cut costs are pretty huge. Honestly, automation is shaping up to be a game-changer for the snack biz — making things more efficient and sustainable all at once.

Revolutionizing Snack Production: Energy Efficiency in Automatic Snacks Frying Machines

The Future of Snack Production: Smart Machines and AI Integration

You know, the snack production world is really going through some major changes right now. A lot of it has to do with smart machines and artificial intelligence (AI) coming into play. I recently came across a report from MarketsandMarkets that says the global market for AI in food and beverage is projected to hit around $13.9 billion by 2025, growing at a crazy rate of 45% annually. It’s pretty impressive! A lot of this growth is driven by new innovations like automatic frying machines that use AI to boost efficiency and make sure the product quality stays top-notch. These machines are pretty smart—they can tweak frying times and temperatures on the fly and even gather data on things like texture, color, and taste so the final product stays consistent every single time.

And it doesn’t stop there. The use of IoT tech in snack production has totally changed the game. For example, research from Statista shows that in 2022, the food processing automation market was already worth about $19 billion, and it’s expected to grow even more. These smart frying machines with sensors can keep an eye on oil quality, which helps cut down waste and makes things safer. All these tech upgrades not only make the whole production process smoother but also let companies respond faster to what consumers want. That means more innovative flavors and fun new snack formats hitting the shelves — pretty exciting times for snack lovers, right?

Revolutionizing Snack Production: 5 Innovative Examples of Automatic Snacks Frying Machines Transforming the Industry

| Machine Type | Automation Level | Features | Production Capacity (kg/h) | Energy Efficiency |

|---|---|---|---|---|

| Continuous Fryer | High | Temperature Control, Oil Filtering | 500 | 80% |

| Batch Frying Machine | Medium | Programmable Cycles, Safety Sensors | 200 | 75% |

| Smart Fryer | Very High | AI Temperature Adjustment, Remote Monitoring | 300 | 90% |

| Oil-less Fryer | High | Air Circulation, Minimal Oil Use | 150 | 85% |

| Multi-Product Fryer | Medium | Interchangeable Baskets, Customizable Settings | 250 | 78% |

Maximizing Efficiency and Quality in Food Production: Insights from Recent Industry Reports on Commercial Frying Equipment

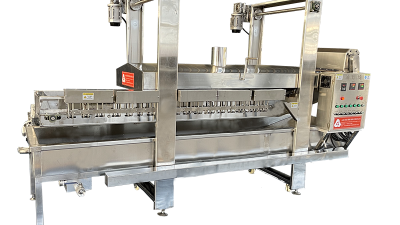

In the competitive landscape of food production, maximizing efficiency and quality is paramount. Recent industry reports indicate that businesses utilizing advanced commercial frying equipment can significantly reduce operational costs while enhancing product quality. One standout innovation in this sector is the Kexinde frying machine, constructed from food-grade stainless steel—this ensures durability and safety in food preparation.

The Kexinde machine features a double-layer conveying belt system that allows snacks to sink thoroughly into the oil, ensuring even cooking and optimal texture. The ability to adjust heating temperatures and frying times according to specific requirements supports the production of perfect snacks tailored to consumer preferences. According to a report from the Food Processing Association, the implementation of automated solutions, such as the Kexinde, can lead to a 20-30% increase in production efficiency, minimizing labor costs and human error while ensuring high-quality output.

Moreover, the advanced technology integrated into the Kexinde frying machine is designed to conserve oil, thus offering a cost-saving advantage for producers. Industry insights reveal that machines with efficient oil usage can lower frying costs by up to 15% without compromising taste or color. This focus on both economic and quality improvements positions the Kexinde as a pivotal investment for businesses aiming to thrive in the evolving food production market.

FAQS

: Key features include precise temperature control systems, automated oil filtration systems, and smart technology for real-time monitoring, all of which enhance frying efficiency and product quality.

Automated oil filtration systems enhance food safety by continuously removing impurities from the oil, extending its life and helping manufacturers deliver fresher and healthier snacks.

Automation reduces energy consumption by ensuring optimal frying conditions, which improves product quality and minimizes waste, helping manufacturers cut operational costs.

Smart technology enables real-time monitoring and adjustments via mobile apps, ensuring consistent quality control throughout the frying process.

AI enhances efficiency and product quality by adjusting frying parameters in real-time and collecting data on texture, color, and taste for consistent results.

The global market for AI in food and beverage is expected to reach $13.9 billion by 2025, growing at a CAGR of 45%.

IoT technologies revolutionize traditional methods by allowing for smart sensors to monitor oil quality, reducing waste and improving safety during production.

Efficient washing systems integrated into advanced frying machines allow for quicker turnaround times between batches, saving on labor costs and contributing to a cleaner production environment.

The food processing automation market was valued at approximately $19 billion in 2022 and is projected to grow significantly.

Automated machines enable manufacturers to quickly adapt to changing consumer preferences in flavors and formats by providing precise and consistent frying outcomes.

Conclusion

Hey, have you checked out the blog titled "Revolutionizing Snack Production: 5 Cool Examples of Automatic Snack Frying Machines Changing the Game"? It really dives into the latest trends shaking up how snacks are made these days. It explains some of the coolest features of modern automatic snack frying machines and how these tech upgrades are not only speeding things up but also boosting product quality. The article even shares some real success stories from top snack brands, showing just how powerful automation really is in transforming the industry.

Plus, it highlights a really important point—energy efficiency. Turns out, these smart machines can help cut down operational costs quite a bit. And looking towards the future, it talks about integrating AI and smarter technology to make snack production even more seamless and clever. Oh, and by the way, Shandong Kexinde Machinery Technology Co., Ltd. is right there at the forefront, pushing these innovations forward and making machinery that adapts to what the market needs now and down the road.

Related Posts

-

Maximize Your Investment with Exceptional After Sales Support for Best Crisp Chips Making Machine

-

Upgrade Your Frying Experience with China Made Best Stainless Steel French Fries Frying Machines

-

Achieving Industry Standards in Potato Chips Production How to Choose the Best Making Equipment

-

The Complete Guide to Sourcing the Best Onion Frying Machine for Your Business

-

Challenges Faced when Using a Potato Chips Maker at Home

-

Explore the Advanced Technical Specifications of the Best Fully Automatic Potato Chips Machine