How to Optimize Your Chicken Nuggets Frying Machine for Maximum Efficiency

Table of Contents

- Understanding the Essential Components of Your Frying Machine

- Assessing Your Current Frying Setup for Efficiency Improvement

- Temperature Control: Key to Perfectly Fried Chicken Nuggets

- Optimal Frying Times: Finding the Sweet Spot

- Routine Maintenance Tips for Longevity and Performance

- Training Staff for Effective Use of the Frying Equipment

- Efficient and Delicious: How a Chicken Nugget Patty Frying Machine Transforms Your Frying Process

- FAQS

- Conclusion

- Related Posts

You know, in the world of food manufacturing, finding ways to make equipment run more efficiently can really make a difference—both in how much you produce and your profit margins. Take the Chicken Nuggets Frying Machine, for example. It’s a crucial part of the process when it comes to making those tasty, fast-food favorites we all love. But to keep it working at its best, you need to regularly calibrate and maintain it. Recent industry insights say that using more advanced frying tech can actually save energy by up to 30%, plus give you even better consistency and quality in your nuggets. Here at Shandong Kexinde Machinery Technology Co., Ltd., we totally get how important this optimization stuff is. We focus on designing, making, and selling food machinery that’s tailored for different sectors, especially fast-food. When you put effort into improving your Chicken Nuggets Frying Machine’s efficiency, not only can you cut down on operational costs, but you’ll also be better equipped to meet growing customer expectations for tasty, high-quality chicken nuggets.

Understanding the Essential Components of Your Frying Machine

When you're trying to get your chicken nuggets just right, it's pretty important to know the main parts that make the frying machine work well. Whether you're using a deep fryer or an air fryer, the heating element really matters. It has to stay at the perfect temperature so your nuggets come out crispy every time—without ending up overdone. Air fryers are pretty clever with those powerful fans—they circulate hot air so evenly, giving you that nice crispiness without using tons of oil. And that’s great because it’s healthier, and honestly, it makes the nuggets taste even better!

Another thing to keep in mind is the size and design of your fryer. If your kitchen is on the smaller side, an air fryer can be a total lifesaver—it’s compact and fits neatly into tight spaces but still does a killer job. Some models even come with preset cooking functions for different foods, which makes the whole frying process way easier. Oh, and don’t forget, regular cleaning and managing the oil properly are super important too. They help your machine last longer and keep everything cooking perfectly — so you, my friend, can always enjoy those delicious, crispy chicken nuggets.

Optimization of Chicken Nuggets Frying Machine Efficiency

Assessing Your Current Frying Setup for Efficiency Improvement

Taking a good look at how your frying setup is working can really make a difference when you're trying to get those chicken nuggets just right, efficiently and without wasting energy. Did you know that, according to the Food Processing Technology Association, about a quarter of the energy used in commercial kitchens actually goes to waste because of outdated equipment or sloppy practices? Crazy, right? By checking out how evenly your fryer heats and how you manage your oil, you might spot some quick improvements. For example, using infrared sensors to keep an eye on oil temperatures can help cut your energy use by around 15%, which adds up!

And don’t forget—regular maintenance is a total game-changer. The National Restaurant Association highlights that cleaning and caring for your fryer properly can actually extend its life by over 30%, saving you money in the long run. Make sure you’re checking the oil quality often and filtering it regularly — bad oil can cause breakdowns and mess up your fry quality. Also, tweaking your frying times and heat based on how much you're cooking at once can help you save even more energy. All these little adjustments not only make your fryer work better but also help you serve up consistently crispy, tasty chicken nuggets. Trust me, a few small changes can really make a big difference!

Temperature Control: Key to Perfectly Fried Chicken Nuggets

When you're frying up chicken nuggets, getting the temperature just right is a total game-changer. It really makes a difference in how good they turn out and how smoothly your fryer runs. At Shandong Kexinde Machinery Technology Co., Ltd., we get it — keeping a steady temperature throughout the process is key to getting that perfect golden-brown exterior, while still locking in moisture and flavor inside. If the heat's all over the place, you risk ending up with undercooked or burnt nuggets, and nobody wants that — plus, it can end up costing you more in the long run.

A good tip is to think about upgrading to a digital temperature control system. Trust me, being able to see and tweak the temperature in real time makes a huge difference. Also, don't forget to recalibrate those sensors now and then — it’s easy to forget, but it keeps your readings accurate and consistent.

And here’s another handy piece of advice: invest in a quality oil filtration system. Keeping your oil clean not only makes it last longer but also prevents the formation of harmful compounds when the oil gets really hot. Plus, your nuggets will taste better and have a nicer texture. With the right tools and a bit of attention to detail, your fryer will run at its best, and you'll be serving up perfectly fried chicken nuggets every single time.

Optimal Frying Times: Finding the Sweet Spot

When you're frying up chicken nuggets, nailing that perfect crunch on the outside while keeping the insides juicy really comes down to hitting the right frying time. If you go too short, you might end up with undercooked, rubbery nuggets, and if you fry them too long, they can get dry and just lose that appetizing texture. My best tip? Do a few small test batches first—adjust the frying time little by little until you get that nice, golden-brown color that screams yum. Usually, keeping the oil between 350 and 375 degrees Fahrenheit works well—it cooks evenly without burning everything to a crisp.

Oh, and don’t forget to use a thermometer to keep your oil temp steady. Fluctuations can mess up the cooking, leaving you with unevenly cooked nuggets or wasted food. Keep an eye on the clock, too—most chicken nuggets need about 3 to 5 minutes in the oil, depending on their size and thickness. Get these timing tricks down, and not only will your nuggets turn out perfect every time, but you’ll also make your frying process smoother and more efficient. Happy eating (and cooking)!

Routine Maintenance Tips for Longevity and Performance

Taking good care of your chicken nugget frying machine is super important if you want it to last and keep working like a charm. I’d recommend setting up a weekly check-up just to see if anything’s worn out or if food bits are piling up. Giving the basket and oil reservoir a good clean is a must — not just to keep things hygienic but also to make sure your nuggets stay tasty and crispy. Just make sure you’re using cleaning products that are safe for food equipment because harsh chemicals can mess up the machine or even compromise food safety.

Another key thing is keeping an eye on the temperature controls. Getting that just right makes all the difference when cooking perfect, crispy nuggets. It’s worth taking a few minutes to calibrate your thermostat now and then — that way, the fryer hits and holds the right temp. Not only will this help you get better results, but it can also save you time and energy in the long run. Oh, and don’t forget about the oil! Regularly filtering and swapping out your oil keeps the flavor fresh and prevents that greasy, off-putting taste. If you give your fryer some love and regular attention, it’ll serve you well for years to come, making your kitchen run smoother and your nuggets even tastier.

How to Optimize Your Chicken Nuggets Frying Machine for Maximum Efficiency - Routine Maintenance Tips for Longevity and Performance

| Maintenance Task | Frequency | Purpose | Estimated Time |

|---|---|---|---|

| Clean Frying Oil Filter | Daily | Remove debris and maintain oil quality | 15 minutes |

| Check Temperature Settings | Weekly | Ensure consistent frying temperatures | 10 minutes |

| Inspect Heating Elements | Monthly | Check for wear and proper functioning | 20 minutes |

| Deep Clean the Fryer | Monthly | Remove built-up grease and residue | 1 hour |

| Replace Old Oil | Every 2-3 days | Maintain oil quality for optimal cooking | 30 minutes |

Training Staff for Effective Use of the Frying Equipment

Getting your staff fully comfortable with using the frying equipment is a real game-changer when it comes to making the most out of your chicken nuggets fryer. First off, it’s a good idea to set up a thorough training program. This shouldn’t just cover how the machine works but also include food safety tips and proper maintenance. You want your team to know the right temperature settings, how long to cook, and portion sizes—that way, you avoid those annoying overcooked or undercooked nuggets. Practical, hands-on training sessions are super helpful here—they give folks a chance to get their hands dirty and really get a feel for the equipment in a low-pressure environment.

And don’t forget, training shouldn’t be a one-and-done thing. Regular refresher courses are a smart move to keep everyone up to speed on the latest best practices and maybe even some new tricks for tray or frying methods. It also helps to promote open chat among your team—sharing tips or sorting out issues together can really boost morale and efficiency. Visual aids, like quick signage near the fryer station, can serve as handy reminders during busy rush hours. Putting in the time and effort into proper training really pays off—your staff will operate the equipment more efficiently, which means better quality chicken nuggets and smoother overall operations.

Efficient and Delicious: How a Chicken Nugget Patty Frying Machine Transforms Your Frying Process

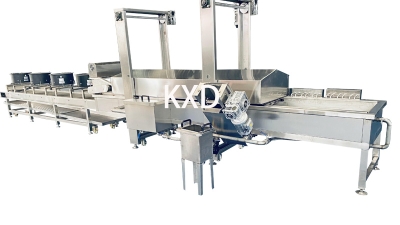

When it comes to frying chicken nuggets, efficiency and quality are paramount. A chicken nugget patty frying machine can significantly transform your frying process by incorporating advanced technology designed to streamline operations while maintaining delectable taste. With options for heating methods ranging from electricity to gas and even electromagnetism, you can choose the best system that suits your commercial kitchen’s needs.

This machine features a customizable frying time and automatic temperature control, allowing you to achieve the perfect crispiness at any temperature between 0-300°C. The double mesh belt not only ensures even frying but also offers adjustable conveyor speed to accommodate various production rates. For those looking to maintain optimal oil quality, an oil filter machine and storage tank can be integrated to prolong the frying oil's life while also enhancing food flavor.

Cleaning is made effortless with a mesh lifting system, ensuring hygiene standards are met without cumbersome maintenance tasks. Safety is another priority; optional fire-extinguishing devices are available to protect kitchen staff and equipment. Moreover, for added convenience and quality, an oil refined filtration device can be incorporated, ensuring that each nugget is fried to perfection using clean, well-maintained oil. This frying machine truly redefines the way you fry, combining efficiency with mouthwatering results.

FAQS

: Routine maintenance is crucial for ensuring both the longevity and optimal performance of the frying machine, preventing wear and buildup of food particles, and maintaining food quality.

Maintenance checks should ideally be scheduled on a weekly basis to examine the machine for any signs of wear or food buildup.

The frying basket and oil reservoir should be cleaned regularly to prevent contamination and maintain the flavor and quality of the chicken nuggets.

It's important to use cleaning agents that are safe for food equipment, avoiding harsh chemicals that can damage components and affect product safety.

Consistent temperature regulation is key for achieving perfectly cooked chicken nuggets, and regular calibration of the thermostat ensures the desired frying temperature is maintained.

Regular filtration and replacement of oil are necessary to prevent off-flavors and ensure a crispy texture in the nuggets.

Effective staff training maximizes the efficiency of the frying machine, ensuring employees understand operational aspects as well as food safety protocols and maintenance practices.

A comprehensive training program should cover operational aspects of the machine, food safety protocols, maintenance practices, proper temperature settings, timing, and portion control.

Simulated hands-on training sessions can help staff become familiar with the equipment in a controlled environment, improving their operational skills.

Regular refresher courses help keep staff updated on best practices and new frying techniques, enhancing their efficiency and knowledge in operating the equipment.

Conclusion

In today's super competitive food scene, making sure your Chicken Nuggets Frying Machine is dialed in is pretty much a must if you want to get that perfect balance of efficiency and top-notch quality. Getting familiar with the main parts of your fryer is actually the first step—kind of like knowing what’s under the hood before you start tweaking things. When you pay close attention to things like maintaining the right temperature and timing your fry just right, those nuggets turn out absolutely delicious—crispy, golden, and exactly what your customers are craving.

Don’t forget, regular upkeep of your equipment isn’t just about avoiding breakdowns; it’s about keeping everything running smooth and ensuring your fryer stays in top shape for the long haul. And training your team on how to use it properly? Total game-changer. If you need some expert advice, Shandong Kexinde Machinery Technology Co., Ltd. has got your back with smart, tailored solutions that’ll help your frying process run more efficiently and keep your operation humming along seamlessly.

Related Posts

-

Advantages of Implementing a Chicken Nuggets Processing Line in Your Manufacturing Business

-

Unmatched Onion Ring Breading Machines from Leading Chinese Manufacturers for Global Excellence

-

Revolutionizing Snack Production: 5 Innovative Examples of Automatic Snacks Frying Machines Transforming the Industry

-

Unlocking Efficiency in Warehousing with the Best Automatic Pallet Washing Machine Insights and Strategies

-

How to Choose the Best Automatic Chips Making Machine for Your Business Needs

-

Maximize Your Investment with Exceptional After Sales Support for Best Crisp Chips Making Machine