Advantages of Conveyor Belt Frying Machines for Efficient Food Processing

Table of Contents

- Benefits of Using Conveyor Belt Frying Machines in Food Processing Operations

- Enhancing Efficiency with Automated Frying Technology

- Cost-Effective Solutions: Reducing Labor and Energy Expenses

- Versatility of Conveyor Belt Frying Systems for Various Food Products

- Ensuring Consistent Quality and Flavor in Fried Foods

- Streamlining Food Safety Standards with Conveyor Frying Equipment

- Exploring the Rise of Commercial Frying Equipment: Insights from Industry Reports on Donut and Chicken Nugget Frying Machines

- FAQS

- Conclusion

- Related Posts

You know, in the fast-changing world of food processing, everyone’s really focused on getting things done efficiently without sacrificing quality. That’s where the Conveyor Belt Frying Machine comes into play — it’s pretty much a game-changer. It helps manufacturers crank up production speeds while still keeping the food consistently good. I read somewhere that according to Allied Market Research, the global market for food processing equipment is expected to hit around $86.9 billion by 2027 — crazy, right? That really shows how much demand there is for smarter machinery like conveyor belt systems.

Companies like Shandong Kexinde Machinery Technology Co., Ltd. are stepping up by offering top-notch food machinery tailored to the needs of different industries — whether it’s food, drinks, or healthcare. By bringing in conveyor belt fryers, businesses can not only make their processes smoother but also get that perfect fry on every batch, which honestly helps boost product quality and makes customers happier too.

Benefits of Using Conveyor Belt Frying Machines in Food Processing Operations

Conveyor belt frying machines really changed the game in the food processing world. They make everything way more more efficient and consistent—it's pretty impressive. One of the biggest perks? They streamline the whole cooking process. You've got food moving nonstop through the fryer, so you get nice, even cooking every single time. That means each piece comes out just right, which definitely boosts the quality of what you're serving and keeps customers happy. Honestly, it’s a real game-changer for ensuring top-notch results.

On top of that, these machines can cut down on labor costs big time compared to traditional frying setups. Because they automate a lot of the frying process, staff don’t have to be glued to the fryer all day, freeing them up for other important tasks. Plus, this automation cuts down on human errors—so stuff's a lot safer and more reliable. Bringing these machines into your production line isn’t just about fancy tech; it’s really an investment that pays off through faster processes, savings on labor, and better quality end products. It’s pretty much a win-win all around.

Enhancing Efficiency with Automated Frying Technology

You know, automated frying tech is really shaking up how we process food these days. It’s all about making things more efficient and getting more consistent results on the production line. With conveyor belt fryers in the mix, food companies can pretty much streamline their operations—cut down on manual work and bump up the output at the same time. These machines do a great job at cooking food evenly because they’ve got controlled heating and keep everything moving smoothly—so no more overcooked surprises, and the final product just tends to be way better.

Lately, we’re also seeing some pretty cool stuff like fully automated restaurants, which just goes to show how clever smart tech is becoming in the food world. As people keep wanting faster, more convenient options, machines like conveyor belt fryers are playing an even bigger role. Companies like Shandong Kexinde Machinery Technology Co., Ltd. are leading the charge and creating high-tech equipment that’s built to meet these shifting needs. By jumping on the automated frying bandwagon, businesses can boost productivity, make smarter use of resources, and stay ahead of what consumers are craving in this super competitive food scene.

Advantages of Conveyor Belt Frying Machines

This chart illustrates the efficiency improvements realized through the automated frying technology of conveyor belt frying machines in food processing. The data reflects average frying times and energy consumption for traditional frying versus conveyor belt systems.

Cost-Effective Solutions: Reducing Labor and Energy Expenses

When you're in the food processing game, conveyor belt frying machines really come with some pretty appealing cost benefits. They can boost efficiency and help your profits grow. I read somewhere, like in a recent report by the Food Processing Association, that switching to automated frying systems can cut down labor costs by almost a third. These machines make the cooking process way smoother — they cut down on the need for manual work and still give you consistent, tasty results every time. So, with that kind of setup, you can free up resources to focus on other important parts of your production, which is a big win.

And it’s not just about saving on labor. Those conveyor belt fryers also help you save on energy bills. The European Energy Efficiency Agency mentioned that newer frying machines use up to 25% less energy compared to the old-school methods. That’s mainly thanks to their better heat transfer tech and smarter cooking cycles. Not only does that improve how well the food gets fried, but it also makes your operation more eco-friendly, which is pretty great.

A couple of tips to keep things running smoothly: make sure to set up regular maintenance for your machines so they stay in tip-top shape. And if you can, look into energy management software — it helps you keep an eye on energy usage and can even help you cut down unnecessary waste. Basically, staying on top of best practices in food processing can really give your bottom line a nice boost.

Versatility of Conveyor Belt Frying Systems for Various Food Products

Conveyor belt frying systems have really shaken things up in the food processing world. They’re super versatile and can handle pretty much any type of food you throw at them — from that perfect crispy snack to delicate pastries. The cool thing is, they help processors get consistent results in flavor and texture no matter what’s on the menu. And with all the recent tech improvements, especially in conveyor design, their flexibility just keeps getting better. For example, new continuous frying systems are now tailored to meet different processing needs, making life a lot easier.

When you’re working with these conveyor belt fryers, here are a couple of tips I’ve found handy:

- First

- always double-check that your fryer’s temperature settings match what you’re cooking.

- Different foods need specific temps for the best results. Also, think about adding filtration systems—keeping your oil clean not only makes your food taste better but also helps your equipment last longer.

- And don’t forget about customizing the setup; playing around with speed and settings can help you get that perfect balance between quick production and top-notch quality, especially when working with a bunch of different recipes.

The world of commercial frying keeps evolving, and new tech is making everything more efficient. Now, you can precisely control the heat and belt movement, which means switching between different foods without losing efficiency is a lot easier. By taking advantage of these advances, food businesses can keep up with the high demand, broaden their product ranges, and stay competitive in this fast-growing market. It’s pretty exciting to see how much closer we’re getting to perfecting the art of fried foods!

Ensuring Consistent Quality and Flavor in Fried Foods

Have you heard about conveyor belt frying machines? They're really changing the game in the food processing world. These days, they help ensure that fried foods come out consistently tasty and perfectly cooked. I was reading a report from MarketsandMarkets back in 2022, and it said that from 2021 to 2026, the global demand for smarter food processing equipment is expected to grow by around 6.5% annually. That’s basically a big shift towards automation and precision—manufacturers want to keep that great flavor while working faster and more efficiently. Thanks to these conveyor systems, the frying temperature stays steady, and the food keeps cooking without interruption, reducing the chances for mistakes and helping produce fried foods that meet all the quality standards we expect.

At Shandong Kexinde Machinery Technology Co., Ltd., we’re pretty proud of what we do. Our team specializes in creating top-notch conveyor belt fryers designed specifically for the food and beverage industry. These machines don’t just speed things up—they also make sure each batch of fried goodies is evenly cooked, keeping that perfect crunch and flavor intact. Plus, studies have shown that keeping a consistent frying temperature can cut oil absorption by up to 30%, which makes the final product healthier without losing that delicious taste we all love. And here’s the exciting part—our machines feature cutting-edge tech that lets operators monitor the cooking process in real-time, opening doors to new possibilities in food processing and helping us serve up higher quality every time.

Streamlining Food Safety Standards with Conveyor Frying Equipment

In today's super busy world of food processing, sticking to high safety standards is more important than ever. Conveyor belt frying machines are a real game changer—they not only boost efficiency but also help make sure safety protocols are followed smoothly. These machines keep the frying temperatures and times consistent, which means your food gets cooked evenly every single time. That’s a big deal because undercooked food can lead to foodborne illnesses—that’s not something we want. Plus, automating the cooking process cuts down on human errors, which are often the cause of safety issues in traditional frying setups.

Quick tip: Make sure you’re regularly checking the frying temp and the quality of the oil. Also, don’t forget about scheduled maintenance on your conveyor systems—you’ll want to keep those running smoothly to avoid any breakdowns that could compromise safety.

Another thing to love about conveyor frying equipment is how easy it is to clean and sanitize. This means you can stay compliant with hygiene standards without too much fuss. Keeping things clean helps prevent cross-contamination, which is super important. And if you need to switch between different food items, these machines make that quick and safe, helping to prevent allergen mix-ups and protecting your customers.

Tip: Use different color-coded tools and equipment for different food types—they’re small changes, but they can really help cut down the risk of cross-contamination in your place.

Exploring the Rise of Commercial Frying Equipment: Insights from Industry Reports on Donut and Chicken Nugget Frying Machines

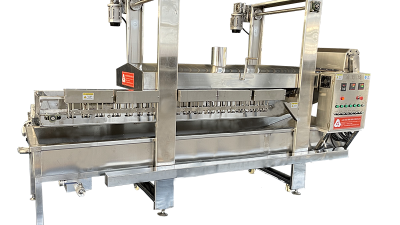

The rise of commercial frying equipment is significantly shaping the landscape of the food industry, particularly in the production of popular snacks like donuts and chicken nuggets. As consumer demands for quality and efficiency increase, advanced frying machines are becoming essential tools for businesses. Among the notable innovations is the Kexinde frying machine, crafted from food-grade stainless steel, which exemplifies the trend towards high-performance, durable equipment suitable for various frying needs.

The Kexinde machine offers a double-layer conveying belt system that ensures food items are immersed thoroughly in oil, achieving a perfect fry every time. This innovative design not only enhances cooking efficiency but also allows for precise adjustments in heating temperature and frying times to meet specific requirements. The fully automated processing means that operators can achieve consistent results with just the push of a button, minimizing labor while maximizing output.

In addition to improving productivity, the Kexinde frying machine employs advanced technology that conserves oil usage while maintaining the flavor and visual appeal of the food. With such equipment, businesses can significantly improve their operational efficiency, reduce costs, and provide high-quality fried products that enhance customer satisfaction. As the industry continues to evolve, investing in state-of-the-art frying machines becomes crucial for companies looking to stay ahead in the competitive market.

FAQS

: Conveyor belt frying systems are advanced machines used in the food processing industry that allow for the efficient frying of various food products while ensuring consistent quality and flavor.

Conveyor belt frying systems optimize cooking by maintaining uniform frying temperatures and enabling continuous cooking processes, which help minimize human error and ensure even cooking.

Yes, these machines are designed to cater to a wide range of food products, from crispy snacks to delicate pastries, due to their versatility and customizable configurations.

Users should optimize temperature settings for specific food items, integrate filtration systems to maintain oil quality, and implement customizable configurations to balance speed and product quality.

Maintaining consistent frying temperatures can improve the quality of fried foods, reducing oil absorption by up to 30% and promoting healthier products without sacrificing taste.

Recent innovations allow for precise heating and belt adjustments, enabling processors to switch between different food items efficiently while maximizing production output.

Automation enhances productivity and consistency in food processing, allowing manufacturers to maintain flavor profiles while meeting high-demand production needs.

Real-time monitoring of cooking parameters in conveyor belt frying machines enables better control over the frying process, resulting in superior product quality and reduced human error.

Yes, industry reports indicate a significant growth in demand for efficient food processing machinery, with an expected CAGR of 6.5% from 2021 to 2026.

Consistent frying ensures that each batch of fried items maintains the desired taste and crunchiness, contributing to overall product quality and customer satisfaction.

Conclusion

The Conveyor Belt Frying Machine really changes the game when it comes to how food is cooked in modern kitchens. Thanks to its automated frying tech, it helps get things done faster, cutting down on manual work and being smarter about energy use. Plus, it's super versatile—you can fry all sorts of different foods, so businesses can meet a bunch of culinary needs without hassle.

And here's the thing: because it carefully controls frying settings, it consistently delivers great quality and flavor, which keeps customers coming back happy. On top of that, using conveyor frying equipment actually makes it easier to stick to food safety standards and stay compliant with industry rules. At Shandong Kexinde Machinery Technology Co., Ltd., we’re really proud of the high-quality food machines we offer. They’re designed to give our clients in the food biz a real boost, helping them succeed every step of the way.

Related Posts

-

Maximize Your Investment with Exceptional After Sales Support for Best Crisp Chips Making Machine

-

Unmatched Onion Ring Breading Machines from Leading Chinese Manufacturers for Global Excellence

-

Leading the Way in Export Strength: The Best Chicken Basket Washing Machine from China

-

15 Best Practices for Maximizing Your Tempura Nugget Line Efficiency

-

How to Choose the Best Automatic Chips Making Machine for Your Business Needs

-

Exploring the Advantages of Using the Best Continuous Fried Tofu Frying Machine in Your Production Line